The prototype stage of a project presents a unique opportunity to optimize design, tune production cost, and identify destabilizing features.

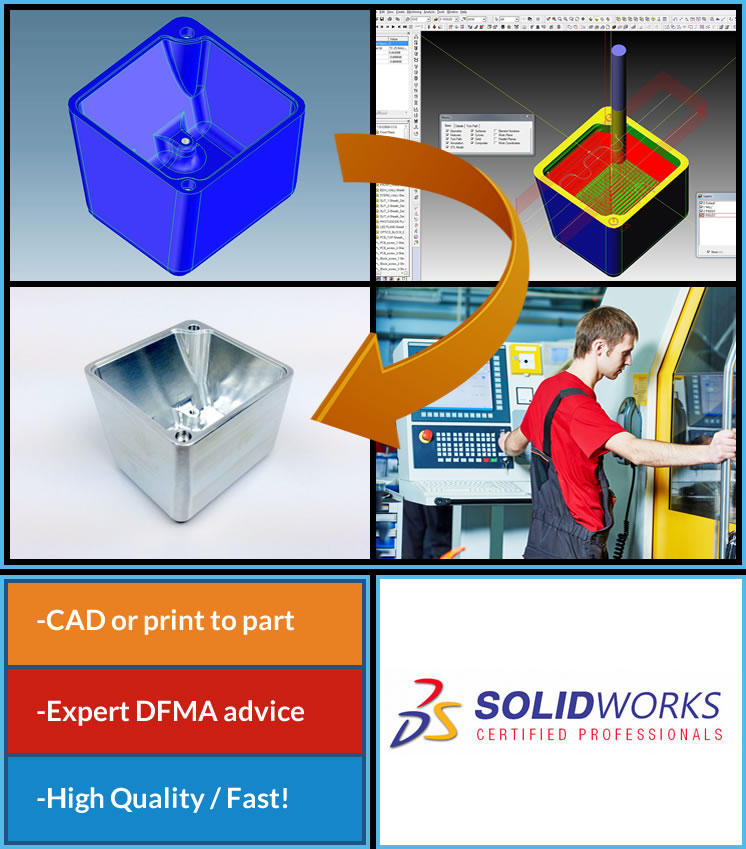

Vetting your design from a production manufacturing perspective, the CCG team can create reliable cost models and offer manufacturing options early on when the design is flexible. We can accomplish this without sacrificing speed or quality by dedicating experienced engineers from our team to your project from start to finish.

By taking this approach, we gain valuable insight into your product’s design and manufacturing process requirements, allowing us to determine how the product will best lend itself to production going forward. CCG utilizes production machining techniques and expert personnel for our prototypes, enabling fast-track cost-benefit discussions with actual measured tolerances and costs.

For our customers, speed, precision and expert advice are all benefits of working with CCG.